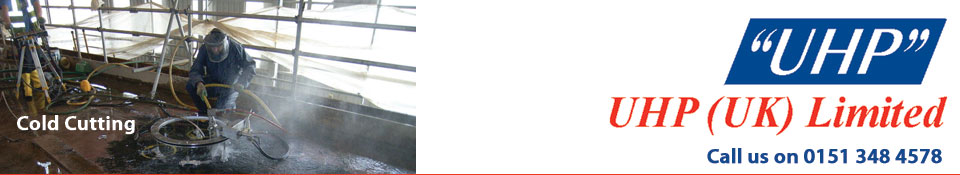

Cold cutting

UHP offers cold cutting to a wide range of applications in the chemical, petrochemical, oil, gas, offshore, construction, power, steel and heavy industries.

|

Cold cutting has a number of significant benefits in relation to traditional cutting techniques which generate friction, heat and sparking and in some application is the only safe and practical way to cutting:

- Cutting virtually any material including steel, concrete and ceramic materials

- Applicable to any thickness

- Spark free, ideal for flammable materials

- No heat generation

- Reduces the need for costly plant shutdown

- Jet cut creates its own start point so does not require an edge or need to overrun.

- The Cutting Head is portable - ideal for restricted areas

- Single pass and multi pass options

- Shock free so can be used for controlled demolition

- Good quality cut so the surface is ready for re-welding.

- No grit contamination or disposal costs

- Environmentally friendly and excellent H&S record - uses no hazardous materials and creates no gases or dust.

- 3,000 bar water jetting equipment with a variety of attachments

|

Cold Cutting Applications |

We have worked across a wide range of projects including:

- Hydrocarbon contaminated pipework

- Access doorways into tanks for cleaning or maintenance

- Decommissioning redundant plant

- Fuel storage tank floors and roofs

- Rubber lined vessels

- Tank cutting

- Concrete cutting

- Hydro demolition

- Underwater cutting

- Cutting of heavy wall thickness

|

Our highly trained staff are available for contracts throughout the UK from our base in the North West.

Please call 0151 348 4578 for a no-obligation quotation for your business or complete the form below for us to contact you:

|